基于FPGA的PID算法学习———实现PID比例控制算法

基于FPGA的PID算法学习

- 前言

- 一、PID算法分析

- 二、PID仿真分析

- 1. PID代码

- 2.PI代码

- 3.P代码

- 4.顶层

- 5.测试文件

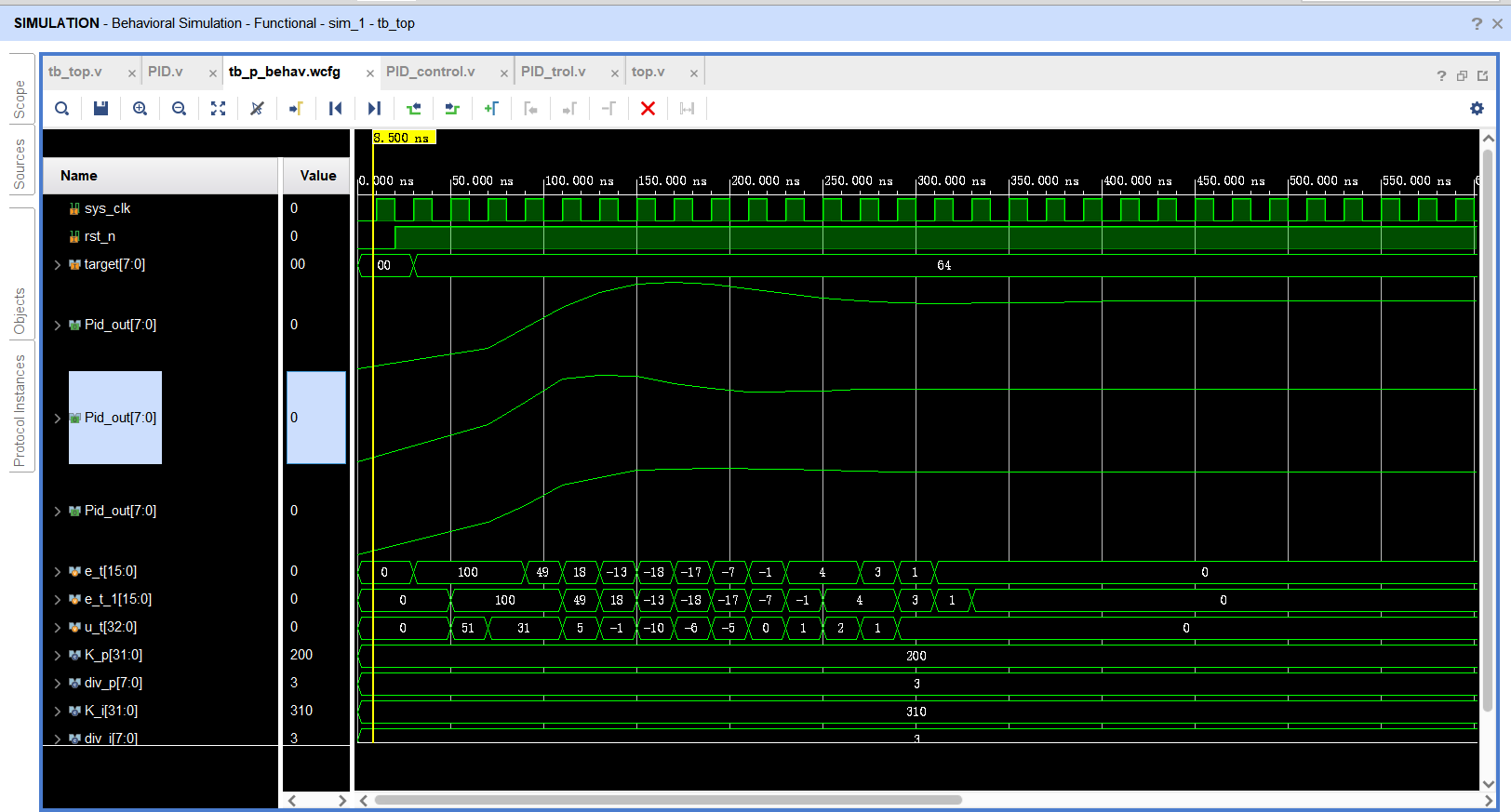

- 6.仿真波形

- 总结

前言

学习内容:参考网站:

PID算法控制

PID即:Proportional(比例)、Integral(积分)、Differential(微分)的缩写。也就是说,PID算法是结合这三种环节在一起的。

闭环控制:输出会影响到输入,进而逐渐逼近目标。

一、PID算法分析

PID比例控制算法:

核心部分,大部分作用来自于P,I和D主要控制减小误差。

目标值:Target

实际值:Pid_out

误差值:e_t

上一时刻误差值:e_t_1

上两个时刻误差值:e_t_2

弥补值:u_t

相关公式:

误差值:e_t=Target - Pid_out

误差值:e_t_1=e_t

误差值:e_t_2=e_t_1

弥补值:u(t)= (Kp * (e(t)-e(t-1)) + Ki * e(t) + Kd * ( e(t)- 2*e(t-1)-e(t-2) ) )

输出值:Pid_out = Pid_out + u(t)

增量式PID:

二、PID仿真分析

1. PID代码

`timescale 1ns / 1ps

//

// Company:

// Engineer:

//

// Create Date: 2025/06/10 17:09:23

// Design Name:

// Module Name: PID

// Project Name:

// Target Devices:

// Tool Versions:

// Description:

//

// Dependencies:

//

// Revision:

// Revision 0.01 - File Created

// Additional Comments:

//

//

module PID(input sys_clk , input rst_n, //signal input signed [7:0] target,output reg signed [7:0] Pid_out);reg signed [15:0] e_t;//目标值和现在值的差距reg signed [15:0] e_t_1;//上一时刻差距reg signed [15:0] e_t_2;//上一时刻差距reg signed [32:0] u_t;//补偿值parameter signed K_p = 32'd100;parameter signed div_p = 8'd3;parameter signed K_i = 32'd250;parameter signed div_i = 8'd3;parameter signed K_d = 32'd50;parameter signed div_d = 8'd3;

// assign e_t = target - Pid_out;always @(posedge sys_clk or negedge rst_n)beginif(!rst_n)begine_t <= 16'd0;endelse begine_t <= target - Pid_out;endendalways @(posedge sys_clk or negedge rst_n)beginif(!rst_n)begine_t_1 <= 16'd0;endelse begine_t_1 <= e_t;endendalways @(posedge sys_clk or negedge rst_n)beginif(!rst_n)begine_t_2 <= 16'd0;endelse begine_t_2 <= e_t_1;endendalways @(posedge sys_clk or negedge rst_n)beginif(!rst_n)beginu_t <= 32'd0;endelse beginu_t <= ((e_t - e_t_1) * K_p )/1000 + ( e_t * K_i)/1000 + ( (e_t -(2* e_t_1) + e_t_2 ) * K_d)/1000 ;endendalways @(posedge sys_clk or negedge rst_n)beginif(!rst_n)beginPid_out <= 8'd0;endelse beginPid_out <= Pid_out + u_t;endendendmodule2.PI代码

module PID_control(input sys_clk , input rst_n, //signal input signed [7:0] target,output reg signed [7:0] Pid_out);reg signed [15:0] e_t;//目标值和现在值的差距reg signed [15:0] e_t_1;//上一时刻差距reg signed [32:0] u_t;//补偿值parameter signed K_p = 32'd200;parameter signed div_p = 8'd3;parameter signed K_i = 32'd310;parameter signed div_i = 8'd3;

// assign e_t = target - Pid_out;always @(posedge sys_clk or negedge rst_n)beginif(!rst_n)begine_t <= 16'd0;endelse begine_t <= target - Pid_out;endendalways @(posedge sys_clk or negedge rst_n)beginif(!rst_n)begine_t_1 <= 16'd0;endelse begine_t_1 <= e_t;endendalways @(posedge sys_clk or negedge rst_n)beginif(!rst_n)beginu_t <= 32'd0;endelse beginu_t <= ((e_t - e_t_1) * K_p )/1000 + ( e_t * K_i)/1000 ;endendalways @(posedge sys_clk or negedge rst_n)beginif(!rst_n)beginPid_out <= 8'd0;endelse beginPid_out <= Pid_out + u_t;endendendmodule3.P代码

module PID_trol(input sys_clk , input rst_n, //signal input signed [7:0] target,output reg signed [7:0] Pid_out);reg signed [15:0] e_t;//目标值和现在值的差距reg signed [32:0] u_t;//补偿值parameter signed K_p = 32'd300;parameter signed div = 8'd3;

// assign e_t = target - Pid_out;always @(posedge sys_clk or negedge rst_n)beginif(!rst_n)begine_t <= 16'd0;endelse begine_t <= target - Pid_out;endendalways @(posedge sys_clk or negedge rst_n)beginif(!rst_n)beginu_t <= 32'd0;endelse beginu_t <= (e_t * K_p )/1000;endendalways @(posedge sys_clk or negedge rst_n)beginif(!rst_n)beginPid_out <= 8'd0;endelse beginPid_out <= Pid_out + u_t;endendendmodule4.顶层

`timescale 1ns / 1ps

//

// Company:

// Engineer:

//

// Create Date: 2025/06/10 13:45:03

// Design Name:

// Module Name: top

// Project Name:

// Target Devices:

// Tool Versions:

// Description:

//

// Dependencies:

//

// Revision:

// Revision 0.01 - File Created

// Additional Comments:

//

//module top(input sys_clk , input rst_n, //signal input signed [7:0] target,output wire signed [7:0] P_out,output wire signed [7:0] Pi_out,output wire signed [7:0] Pid_out);PID u_PID (.sys_clk (sys_clk),.rst_n (rst_n),.target (target),.Pid_out (Pid_out) );PID_control u_PI (.sys_clk (sys_clk),.rst_n (rst_n),.target (target),.Pid_out (Pi_out) );PID_trol u_P(.sys_clk (sys_clk),.rst_n (rst_n),.target (target),.Pid_out (P_out)

);

endmodule5.测试文件

`timescale 1ns / 1ps

//

// Company:

// Engineer:

//

// Create Date: 2025/06/10 13:48:03

// Design Name:

// Module Name: tb_top

// Project Name:

// Target Devices:

// Tool Versions:

// Description:

//

// Dependencies:

//

// Revision:

// Revision 0.01 - File Created

// Additional Comments:

//

//`timescale 1ns / 1psmodule tb_top();// 输入信号reg sys_clk;reg rst_n;reg signed [7:0] target;// 输出信号wire signed [7:0] P_out;wire signed [7:0] Pi_out;wire signed [7:0] Pid_out;// 实例化顶层模块top u_top (.sys_clk (sys_clk),.rst_n (rst_n),.target (target),.P_out (P_out),.Pi_out (Pi_out),.Pid_out (Pid_out));// 时钟生成(100MHz)initial beginsys_clk = 0;forever #10 sys_clk = ~sys_clk; // 10ns周期 = 100MHzend// 测试激励initial begin// 初始化并复位rst_n = 0;target = 0;#20; // 等待两个时钟周期// 释放复位rst_n = 1;#10;// 测试场景 1:正目标值target = 8'd100; // +50endendmodule6.仿真波形

总结

简单测试,有问题欢迎交流