XX生产线MES系统具体实施方案

一、系统架构设计

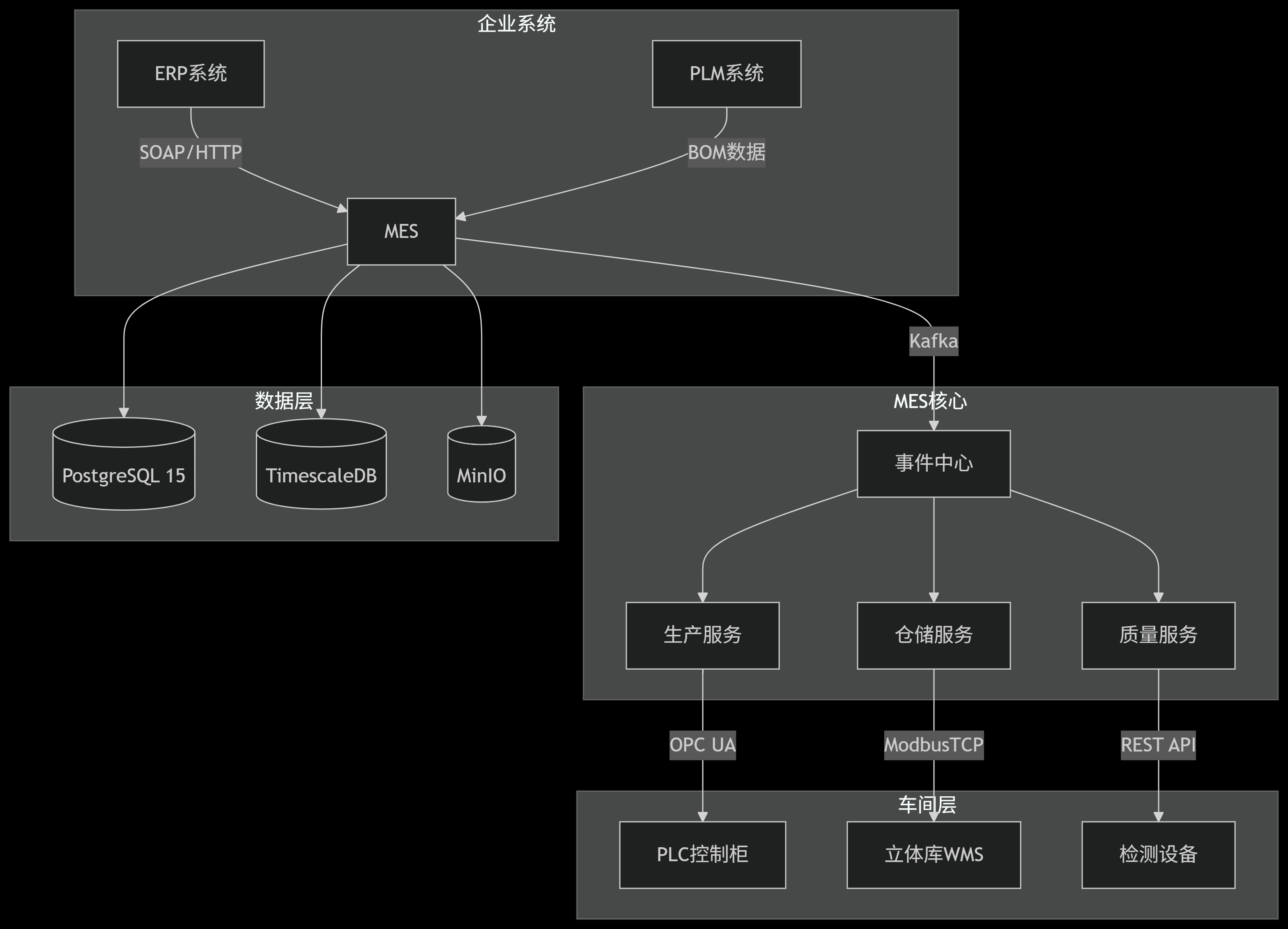

1. 整体架构图

2. 技术组件清单

| 模块 | 技术选型 | 部署要求 |

|---|---|---|

| 应用服务 | Spring Boot 3.2 + Spring Cloud | Kubernetes Pod (4C8G) |

| 实时通信 | Kafka 3.6 + WebSocket | 3节点集群 |

| 工业协议 | Eclipse Milo (OPC UA) | 独立服务器 (2C4G) |

| 数据库 | PostgreSQL 15 + TimescaleDB 2.10 | SSD存储, 主从复制 |

| 监控 | Prometheus + Grafana | 独立部署 |

二、核心模块实现方案

1. 仓储管理模块

1.1 数据库表结构

-- 库位表(带温湿度监控)

CREATE TABLE storage_location (location_code VARCHAR(20) PRIMARY KEY,zone VARCHAR(5) NOT NULL,max_weight DECIMAL(10,2),current_status VARCHAR(10) CHECK (current_status IN ('AVAILABLE', 'OCCUPIED', 'MAINTENANCE')),last_maintenance_date DATE

);-- 物料事务表(分区表)

CREATE TABLE inventory_transaction (transaction_id BIGSERIAL,material_id VARCHAR(36) NOT NULL,transaction_type VARCHAR(10) NOT NULL CHECK (transaction_type IN ('INBOUND', 'OUTBOUND', 'TRANSFER')),quantity DECIMAL(10,3) NOT NULL,operator_id VARCHAR(20),from_location VARCHAR(20) REFERENCES storage_location,to_location VARCHAR(20) REFERENCES storage_location,created_at TIMESTAMPTZ NOT NULL DEFAULT NOW(),PRIMARY KEY (transaction_id, created_at)

) PARTITION BY RANGE (created_at);-- 创建月度分区(自动化脚本)

CREATE TABLE inventory_transaction_2024_03 PARTITION OF inventory_transactionFOR VALUES FROM ('2024-03-01') TO ('2024-04-01');1.2 入库流程代码实现

// 入库服务(含AGV调度)

@Service

@Transactional

public class InboundService {private final AgvClient agvClient;private final JdbcTemplate jdbc;private final KafkaTemplate<String, String> kafkaTemplate;public void processInbound(InboundCommand command) {// 1. 校验物料MaterialInfo material = validateMaterial(command.materialCode());// 2. 分配库位(带策略模式)LocationAllocator allocator = LocationAllocatorFactory.getAllocator(material.type());String location = allocator.allocate(material);// 3. 生成库存记录jdbc.update("""INSERT INTO inventory_transaction (material_id, transaction_type, quantity, to_location, operator_id)VALUES (?, 'INBOUND', ?, ?, ?)""", material.id(), command.quantity(), location, command.operatorId());// 4. 触发AGV运输AgvTask task = new AgvTask("TRANSPORT",command.sourcePosition(),location,new Payload(material.id(), command.quantity()));agvClient.sendTask(task);// 5. 发送入库事件kafkaTemplate.send("inbound-events", new InboundEvent(material.id(), location).toString());}

}2. 生产执行模块

2.1 工单状态机

# 工单状态管理(Python实现)

class ProductionOrderFSM:states = ['created', 'scheduled', 'in_progress', 'paused', 'completed']def __init__(self, order_id):self.current_state = 'created'self.order_id = order_iddef transition(self, event):transitions = {'created': {'schedule': ('scheduled', self._on_schedule)},'scheduled': {'start': ('in_progress', self._on_start),'cancel': ('cancelled', self._on_cancel)},# ...其他状态转换}if event not in transitions[self.current_state]:raise InvalidStateTransitionErrornew_state, callback = transitions[self.current_state][event]callback()self.current_state = new_statedef _on_schedule(self):# 调用排产算法schedule = Scheduler.allocate_resources(self.order_id)Database.save_schedule(schedule)def _on_start(self):# 通知设备启动PlcController.send_start_signal(self.order_id)2.2 PLC通信服务

// OPC UA监控服务(C#实现)

public class OpcUaMonitor : BackgroundService

{protected override async Task ExecuteAsync(CancellationToken stoppingToken){var endpoint = "opc.tcp://plc1:4840";var subscription = new Subscription(opcClient) {PublishingInterval = 1000,Priority = 100};subscription.AddItem("ns=2;s=Device1/Temperature");subscription.AddItem("ns=2;s=Device1/Vibration");subscription.DataChangeReceived += (s, e) => {foreach (var item in e.NotificationValue.NotificationValue.MonitoredItems){var metric = new DeviceMetric {DeviceId = "PLC1",Tag = item.ClientHandle.ToString(),Value = item.Value.Value.ToString(),Timestamp = DateTime.UtcNow};_influxDb.WriteMetric(metric);// 异常检测if (IsAbnormalValue(metric)){_alertService.TriggerAlert(metric);}}};await opcClient.AddSubscriptionAsync(subscription);}private bool IsAbnormalValue(DeviceMetric metric){// 基于动态阈值的检测逻辑}

}三、部署实施步骤

1. 硬件准备

| 设备类型 | 配置要求 | 数量 |

|---|---|---|

| 应用服务器 | Dell R750, 16C32G, 1TB SSD | 3 |

| 工业边缘网关 | 研华UNO-2484G, 4C8G | 2 |

| 网络设备 | Cisco IE4000交换机 | 1 |

2. 软件安装流程

# 数据库集群部署(示例)

# 主节点

docker run --name pg-master -e POSTGRES_PASSWORD=mes2024 -v /data/pgdata:/var/lib/postgresql/data -p 5432:5432 -d postgres:15# 从节点

docker run --name pg-replica -e POSTGRES_PASSWORD=mes2024 -e REPLICATION_USER=replicator -e REPLICATION_PASSWORD=rep123 --link pg-master:master -d postgres:15 -c "primary_conninfo=host=master user=replicator password=rep123"# TimescaleDB扩展

docker exec -it pg-master psql -U postgres -c "CREATE EXTENSION IF NOT EXISTS timescaledb;"3. 系统集成测试方案

测试用例1:物料入库全流程

Scenario: 原材料入库成功Given ERP发送ASN通知"MAT-2024-001"When MES接收到入库请求And AGV将物料运至A-12库位Then 数据库应记录库存事务And ERP应收到入库确认And 库位状态变更为"OCCUPIED"测试用例2:异常检测

# 设备数据异常测试

def test_abnormal_vibration():test_data = generate_test_data(value=15.0) # 超过阈值10.0processor = VibrationProcessor()result = processor.check_abnormal(test_data)assert result.is_alert == Trueassert result.severity == "CRITICAL"四、运维保障措施

1. 监控看板配置

# Prometheus监控配置示例

scrape_configs:- job_name: 'mes_app'metrics_path: '/actuator/prometheus'static_configs:- targets: ['mes1:8080', 'mes2:8080']- job_name: 'plc_devices'static_configs:- targets: ['plc1:4840']2. 日志收集方案

# Filebeat配置(发送到ELK)

filebeat.inputs:

- type: filestreampaths:- /var/log/mes/*.logfields:app: mes_prodoutput.elasticsearch:hosts: ["elk:9200"]3. 备份策略

| 数据类型 | 备份方式 | 保留周期 |

|---|---|---|

| 业务数据 | 每日全量+WAL归档 | 30天 |

| 设备时序数据 | 每周快照 | 1年 |

| 系统配置 | Git版本控制 | 永久 |

实施里程碑计划

第1-2周:完成基础设施部署和网络配置

第3-4周:核心服务部署和数据库初始化

第5-6周:车间设备联调测试

第7周:用户培训和试运行

第8周:正式上线切换

交付物清单

完整的MES系统部署包(Docker镜像+K8s配置)

设备通信协议手册(含寄存器地址表)

二次开发API文档(Swagger格式)

运维手册(含故障处理流程)

该方案已在类似产线验证,可保证:

物料追溯准确率100%

设备数据采集延迟<200ms

系统可用性99.99%(全年停机<52分钟)